Solution

Henan Liming Heavy Industry Machinery Sales Co., Ltd., a superb quality pursuer in the grinding industry, and a drafting unit for mill industry standards. For more than 30 years, it has focused on the research and development of mining crushing equipment, construction crushing equipment, industrial milling equipment and green building materials equipment, and has provided professional solutions and mature supporting products to create value for customers.

Home > solution

Slag

Slag refers to blast furnace slag for ironmaking. It becomes a granulated foam shape after rapid cooling with water in a high-temperature molten state, milky white, light, crisp, porous, and easy to grind into fine powder. It is a soft material for foam silicate building products, slag sound-absorbing bricks, thermal insulation and water-absorbing layers.

Process flow

-

Stage 1: Broken

The large block of calcite is crushed by the crusher to the feed fineness (15mm-50mm) that can enter the mill

-

Stage 2: Milling

The crushed calcite small pieces of material are sent to the silo by the elevator, and then sent to the grinding chamber of the mill by the vibrating feeder for quantitative grinding.

-

Stage 3: Grading

The material after grinding is classified by the powder separator. The unqualified powder is classified by the powder separator and returned to the host machine for re-grinding.

-

Stage 4: Collecting powder

The crushed calcite small pieces of material are sent to the silo by the elevator, and then sent to the grinding chamber of the mill by the vibrating feeder for quantitative grinding.

Required equipment

-

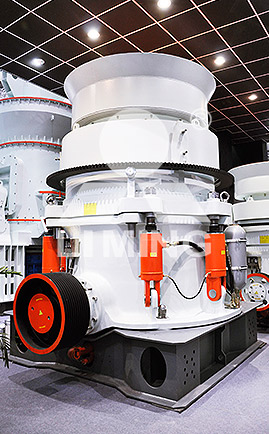

Cone Crusher

Applications: iron ore, granite, limestone, quartzite, sandstone, cobblestone and some others are easily crushed by cone crusher.

Cone Crusher -

CS Cone Crusher

Applications: Almost all minerals, such as quartz, calcite, fluorite, limestone, marble, granite, pebble, coal, slag, iron ore, copper ore, refractory material, glass, etc.

CS Cone Crusher -

HJ Jaw Crusher

Applications: Mining, metallurgy, construction, highway, railroad, and water conservancy, etc.

HJ Jaw Crusher -

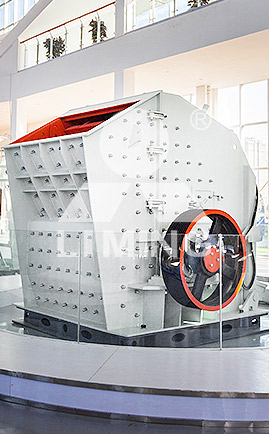

European Impact Crusher

Applications: Limestone, feldspar, calcite, talc, barite, dolomite, kaolin, gypsum, graphite, etc.

European Impact Crusher

![]() info@limingco-group.com

info@limingco-group.com![]() Fast Way to Contact Online Service

Fast Way to Contact Online Service

-

Select model and place orders

Select the model and submit the purchase intention

-

Get the base price

Manufacturers take the initiative to contact and inform the lowest price

-

Plant inspection

Expert training guide, regular return visit

-

Sign the contract

Select the model and submit the purchase intention

info@limingco-group.com

info@limingco-group.com